From rapid inline inspection and automated atline inspection to detailed NIO analysis, our sensors ensure stable processes, reduce waste, and guarantee the highest quality.

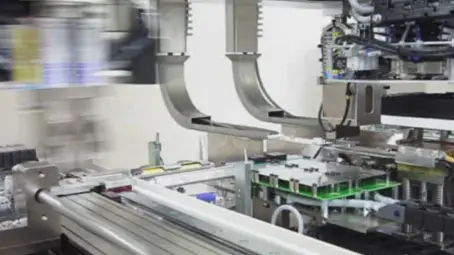

Video: Xactools GmbH

Our 3D sensors accompany the entire lifecycle of products and processes – from development and manufacturing to the analysis of rejected parts. Whether in-line, at-line, in the quality lab, or in early R&D, the same measurement technology is used everywhere. This guarantees 100% comparable data, enables deeper process knowledge, and delivers real insights for continuous improvements.

Early design and process validation with production-identical measurement technology – insights flow directly into product improvements.

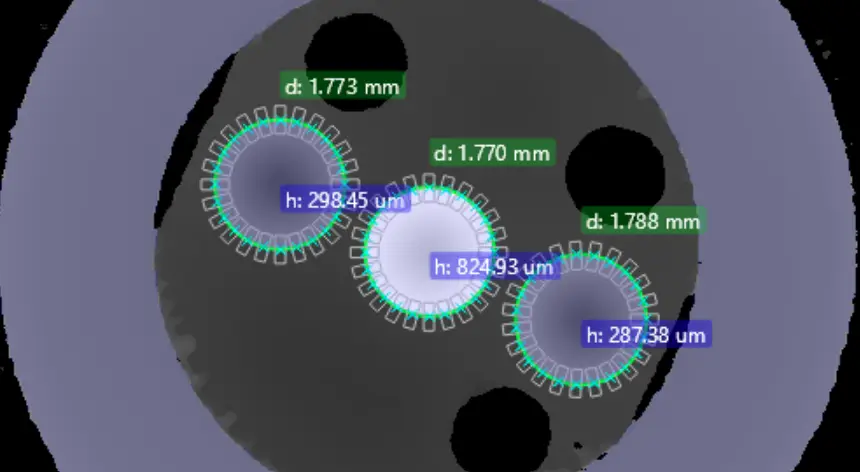

Automated sampling and re-checks according to exactly the same criteria as in-line.

Inspection in machine cycle with SPC-capable data and immediate process feedback.

In-depth root cause analyses of NIO parts with identical calibration and database.

Our sensors are based on a uniform measuring principle. In each phase of the product lifecycle, this is expanded by complementary services – be it dedicated software, our machine vision platform, or integration support. This creates exactly the solution that producers need in R&D, ramp-up, series production, and the laboratory.

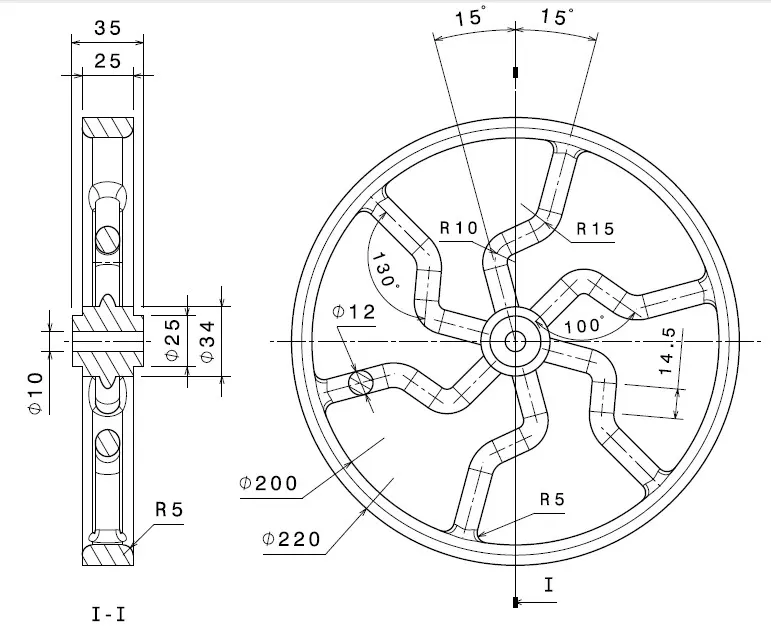

With Heliotis’ production-identical measurement technology, development time can be significantly reduced: The heliProfiler P4 enables automated 3D measurements as early as the design and process phase. Extensive measurement sequences run independently and provide large amounts of data for well-founded analyses – without permanent personnel commitment.

This allows variants to be compared more quickly, processes to be validated earlier, and findings to be fed directly back into development.

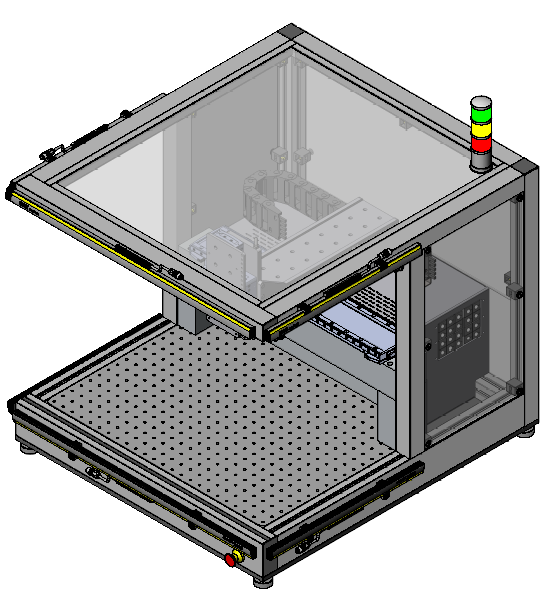

Industrial XY portal for precise 3D measurements in R&D and pre-series. High repeatability, variable designs, and compatibility with all Heliotis 3D cameras enable flexible measurement setups for components of various geometries.

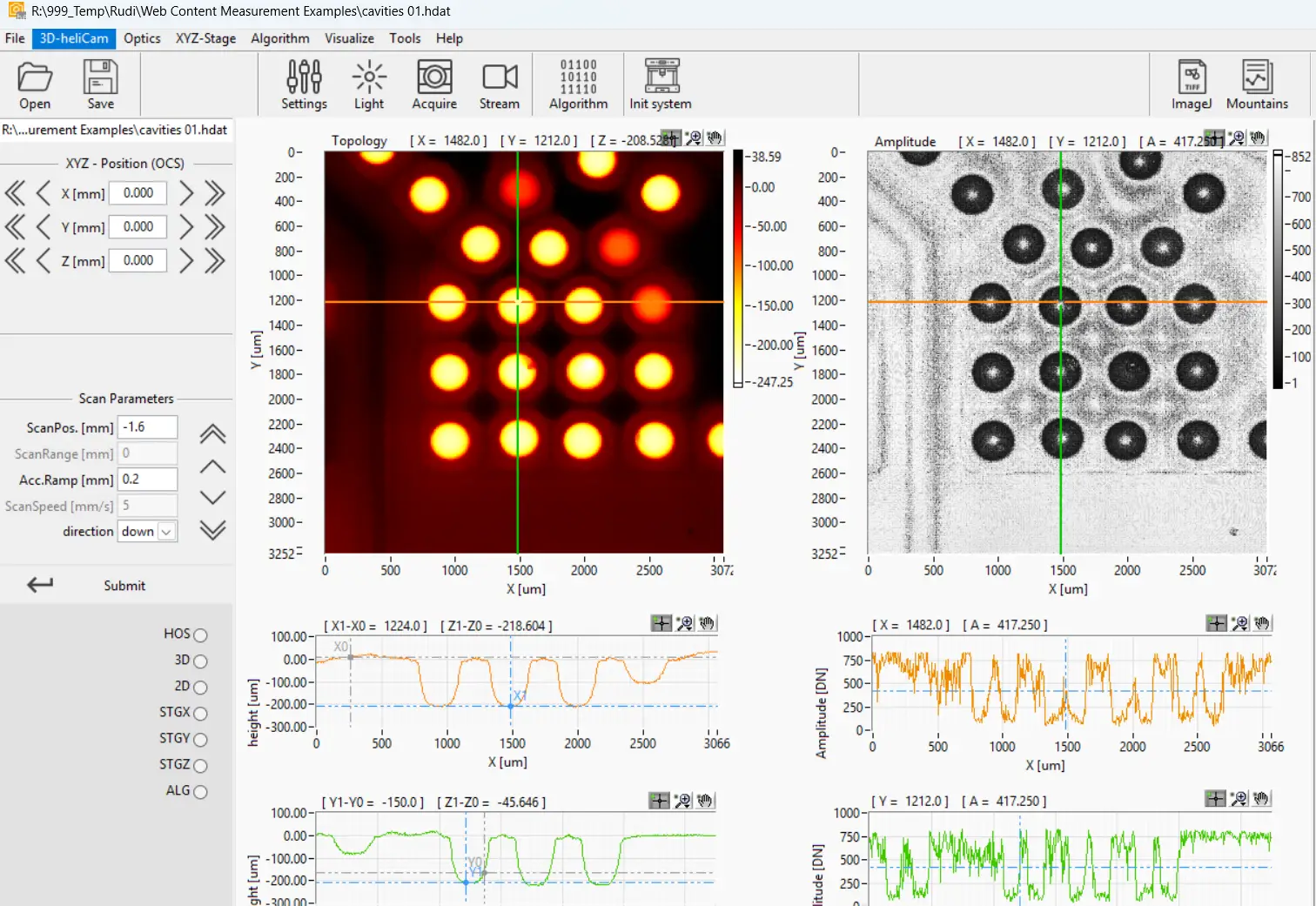

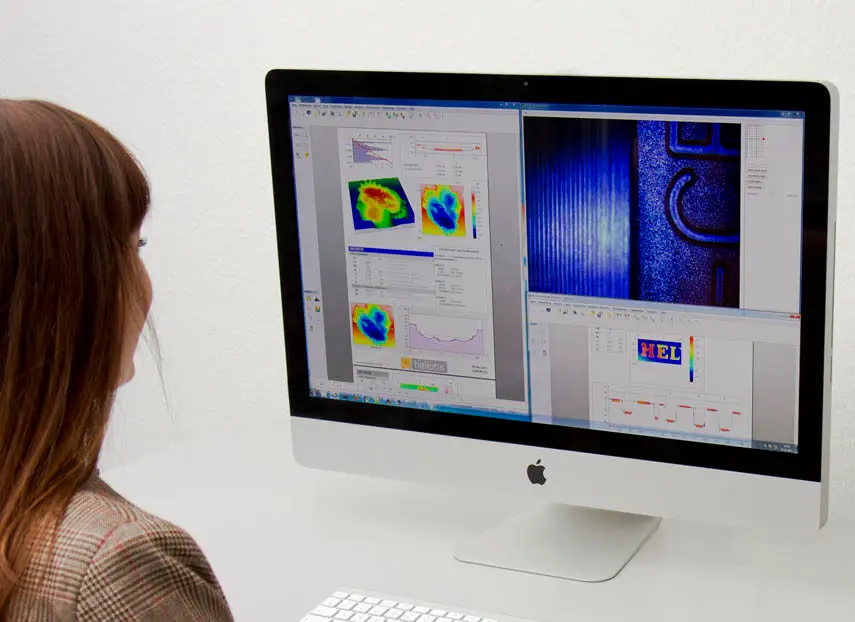

Interactive control and automated sequences combined with comprehensive 3D analysis. With the integrated MountainsMap® environment, topographies can be evaluated immediately, analyzed according to ISO 25178 standards, and documented as a report.

Robust, production-ready XY portal for at-line 3D measurements in ramp-up. Quickly deployable as a standard product, cost-efficient, and compatible with all Heliotis 3D sensors. Ideal for process validation and a stable transition to series production.

Based on the Heliotis MV platform, the solution offers automated image evaluation based on Halcon. The user interface and data interfaces are adapted to the process and infrastructure according to the specifications – for seamless integration into existing manufacturing environments.

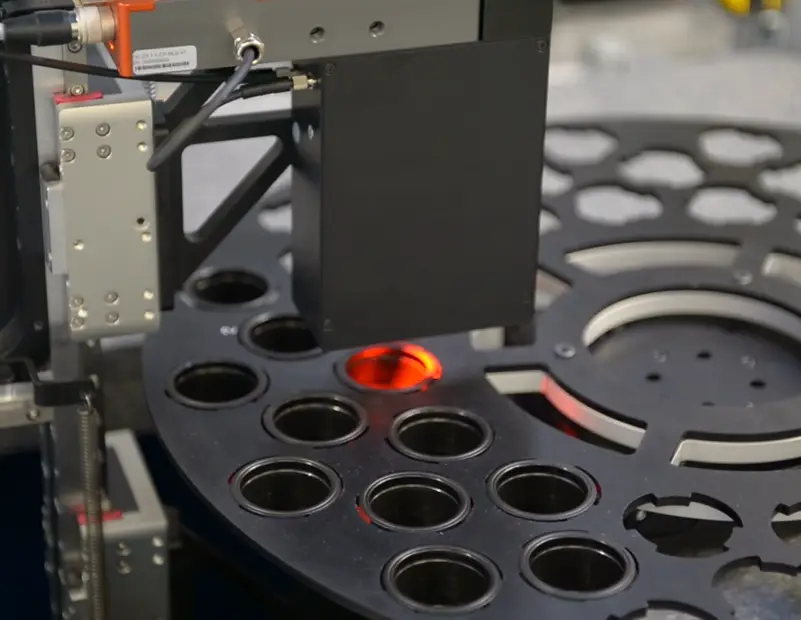

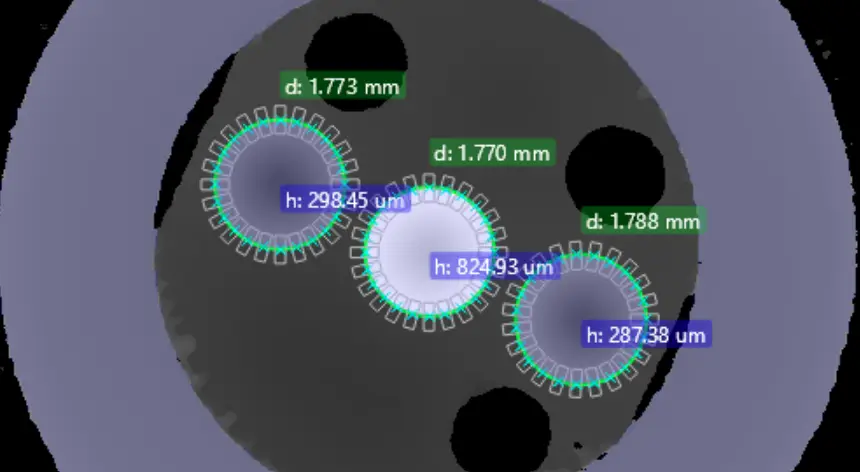

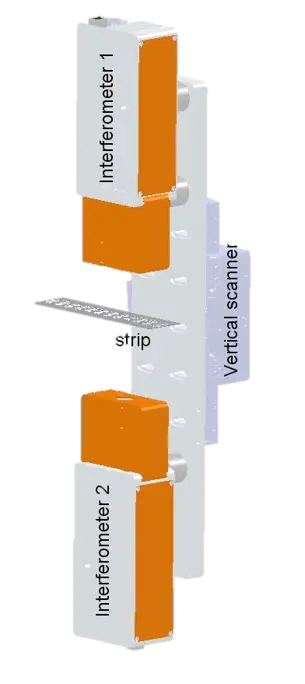

High-precision 3D measuring head with maximum vertical resolution for demanding in-line inspections. Ideal when highest accuracy is required for small to medium-sized measuring fields.

High-precision 3D measuring head with extended field of view and high measuring speed. Perfect for large-area or cycle-time-critical in-line inspections in series production.

The in-line app is based on the same Halcon code base as the at-line solution from phase 2. Existing algorithms, experience, and investments can be fully reused – for seamless integration into automated inspection stations and series production systems.

Optional industrial interface for direct connection of the heliInspect™ sensors to the system PLC. Supports standard protocols such as PROFINET® and EtherCAT® and enables real-time synchronization of trigger, status, and measurement signals – for seamless integration into automated production lines.

Not all defects can be automatically classified in the line. For this reason, conspicuous parts are examined in the measurement laboratory using the same measurement technology as in production – precise, traceable, and interactive.

The insights gained flow directly back into product development, process optimization, and the further development of in-line inspection.

The precise XY portal is used in the measurement laboratory for detailed analysis of NIO parts. With the same 3D sensors as in the line, error patterns can be precisely traced and deviations can be quantified – with full compatibility to all Heliotis measuring heads.

Interactive measurement and analysis environment for the evaluation of NIO parts. The results provide valuable insights for process optimization, product adaptation, or the expansion of the in-line app.

Heliotis checks in a clearly structured process whether our sensors are suitable for your inspection task. The aim is to rule out risks early on and not waste any time. Thanks to our well-equipped test center and experienced application engineers, you will receive well-founded results within a short time – an initial test report is free of charge and without obligation for you.

In a brief exchange, we clarify the goal, requirements, and framework conditions of your measurement task. This ensures that the test measurements are targeted and meaningful.

Our application engineers carry out measurements on your sample components and analyze the results. You will receive a structured test report as well as a joint discussion of the results.

Based on the preliminary investigations, we develop a proposal for the concrete implementation – including mechanical integration, interfaces, and image processing. If required, we involve experienced partners.